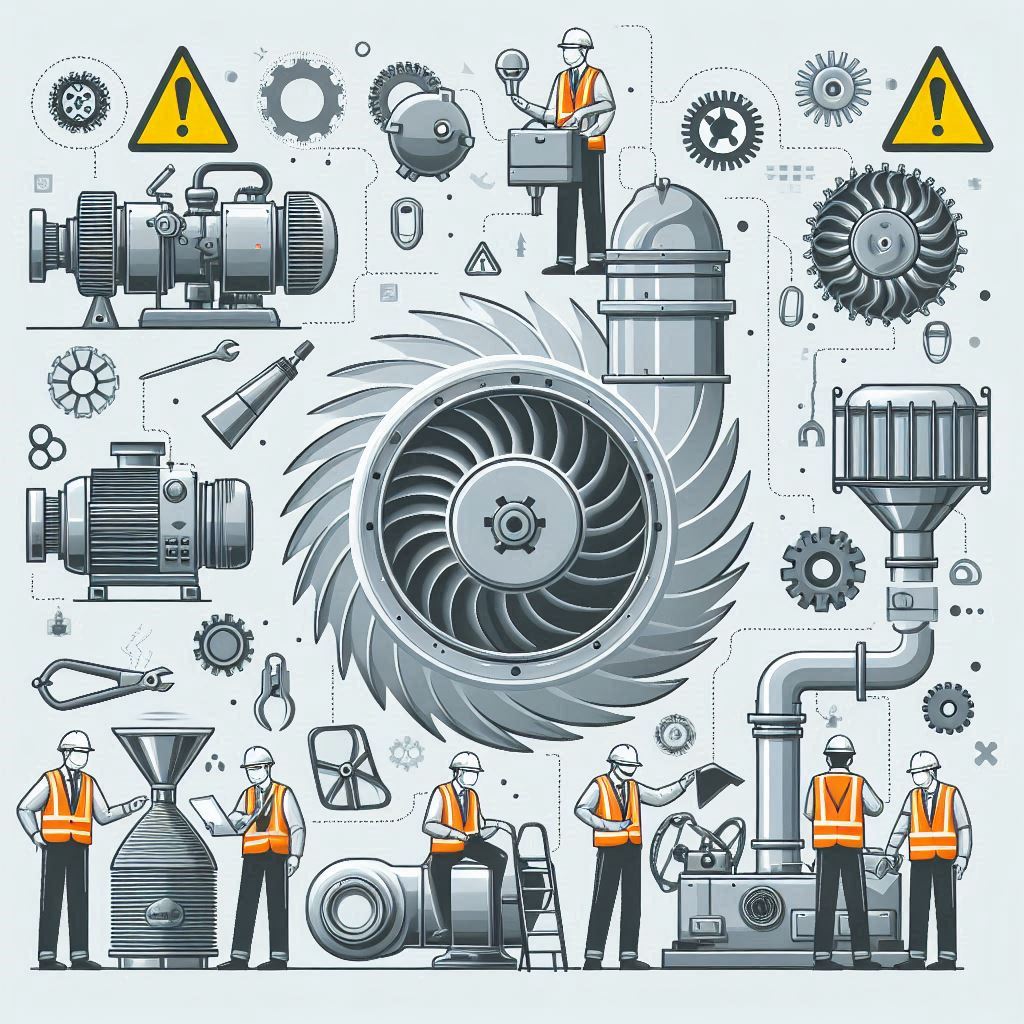

Safety guidelines for air blower operation and handling

What is an air blower?

The best air blowers in India are designed to take in air from an inlet and expel it at an outlet while increasing the speed and air volume.

Many workplace accidents and injuries have occurred because a worker improperly uses an industrial blower. To prevent injuries and accidents in the workplace, your employees must understand how to use the best air blowers in India safely.

Improper installation may result in electric shock, injuries from contact with moving parts, and other potential hazards. It is advisable to seek installation help from the blower manufacturers.

Fundaments to check when installing an air blower

1. Planning: Proper planning is essential for the efficient installation of industrial air blowers and to ensure the following:

- Review installation documents, including requirements for fire and explosion protection, minimum hood and duct velocities

- Review the operating conditions and verify locations for test ports, balance valves, dampers, and fittings.

- Review the ventilation system design to ensure all access doors are closed and duct interferences have been checked and removed.

- Review the operating needs of the blower, motor, and drive system

- The location for installing a fan is complete and ready to accept the air blower.Cranes, tools, and equipment required for installation

- Trained personnel are available and prepared to handle the blower.

- Prepare an installation, begin the start-up evaluation process, and share it with all the plant personnel.

2. Receiving: Inspect the shipment while receiving your blower for damage or shortage. Examine the blower for scrapes, dents, broken parts, shafts, and more. Compare paperwork with items being received. Make sure that all the details are present, assembled correctly, and in working order.

3. Handling: It is essential to carry the air blower as per the instructions: The components of the blower need to be shifted with great care as minute damage in any part disturbs the working condition of the device.

4. Placement: Always place the blower on a level surface. One should not position the air blower so close to the wall that the cooling airflow is obstructed. The air blower must be adequately grounded. It is advisable to install the air blower indoors. In case you prefer to install the air blower outside, protect it from the weather condition. Ventilate the blower room to ensure the optimum equipment, performance, and longevity. The industrial air blower must be isolated from any vibration close by.

5. Electric supply: Before installing the blower, ensure your electrical service voltage matches the voltage on the blower nameplate. The air blowers must be wired internally for proper voltage. It is advisable to get all the wiring and electric connection work done by a trained electrician as per the prescribed standards.

6. Start-up: Precautions must be taken before starting up the fan. Ensure all the safety accessories are installed before starting the blower fan. Do not exceed the maximum RPM stated for the blower.

Wrap up

Want to know more about industrial air blowers? Connect with the best blower manufacturers in India and get updates and knowledge.