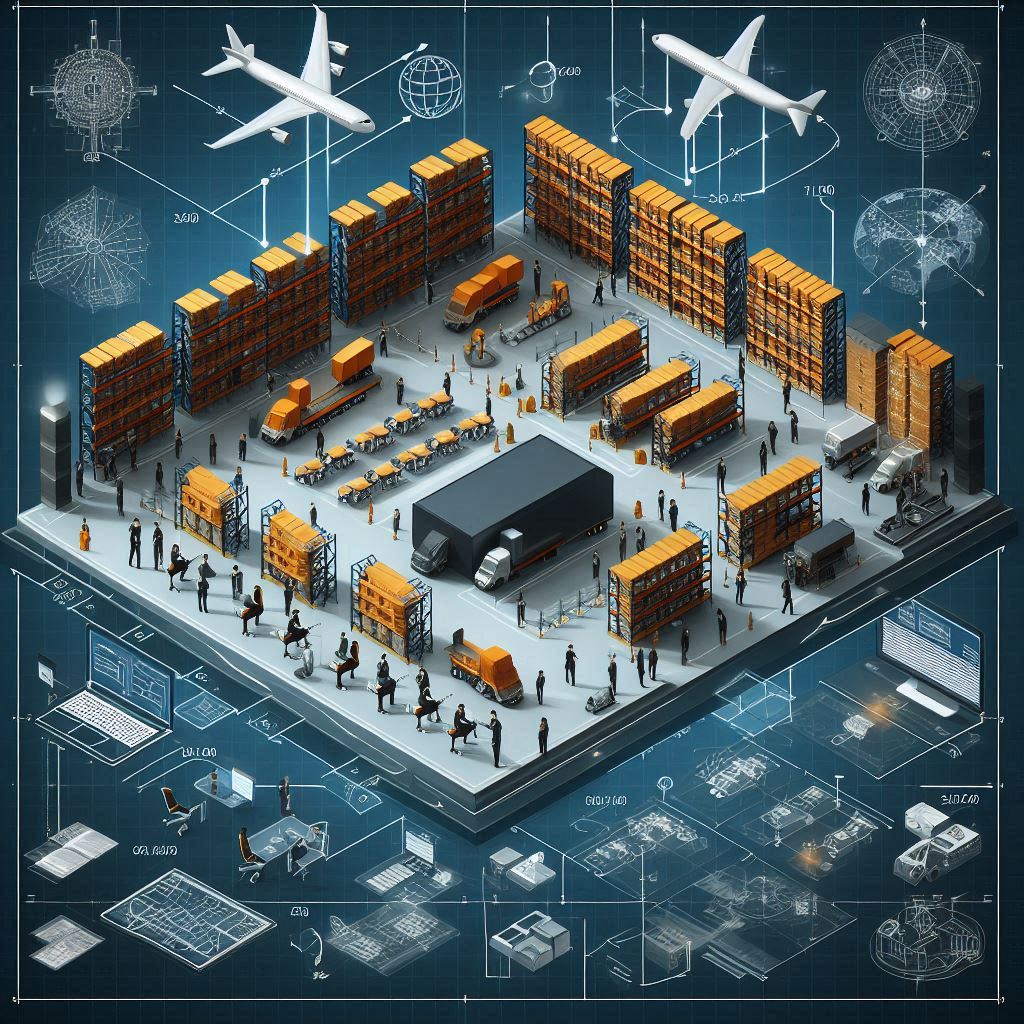

Ware house space optimization: Strategies for efficient layout and utilization

Warehouse is important in the logistic business. Warehouse is the place where goods are stored safely till they are transported to their final destination or stored for further transportation.

It is important to have warehouse space optimization for hassle-free movement of goods. A good warehouse layout streamlines workflow and creates faster shipping times. It the space of the ware house is not utilized effectively, it can adversely affect the shipping times, workflow and supply chain.

Here are some of the strategies for efficient layout and utilization

1. Vertical stacking of the inventory: Warehouse space can be increased by stacking the inventory vertically. This process allows taking boxes and pallets upward instead of consuming square footage that is required for machines, equipment and high-traffic areas. Organize racking system so that the product s one picks up most frequently are placed along the bottom rows and are easy to access.

2. Excess stock in trailers: Another way for efficient layout utilization of the warehouse space is consider taking seasonal items or excess stock to a separate location. In case there are products in the warehouse that is not required for weeks or months, then it is advisable to store them in a temperature controlled storage unit or trailer. This approach leaves rooms for those items that are shipped and sold more often.

3. Zone assignment in warehouse: Productivity of the warehouse is enhanced by assigning areas for specific tasks like packaging, labeling, receiving and picking. Organizing warehouse space into zones informs the workforce about the safer place to finish the tasks. It can also prevent the overcrowding spots in the warehouse.

4. Warehouse management system: Deploying warehouse management system is best for optimizing warehouse space and layout. The system distributes goods in warehouse on the basis of algorithms and rules. The system reduces good movement and ensures accurate inventory management.

5. Space for scalability: The efficient warehouse layout optimization should be designed to meet organizations current and future goals. It is important set up a storage space for more orders, or expanding floor space for loading docks.

6. Right equipment: The warehouse needs the right equipment for operations. Different types of products need different material handling equipment that will affect the spacing of the equipments.

7. Separate reception area: Keeping the reception areas separate enables efficient sorting and inspection of the goods. Everything that is received in the warehouse needs to be checked and reviewed so it is imperative to keep this area separate from the rest of warehouse. Ample space provides accurate product inspections and prevents bottle-necks.

8. Organize storage area: It is advisable to separate dynamic and static storage. Dynamic is section of warehouse for famous items and static is for that products that are stored for little before they are shipped. Differentiating these two areas can prevent inventory errors.

Wrap up

Effective warehouse layout improves usage space and enhances the productivity of the warehouse. It also ensures businesses achieve their goals and deliver the products to customers on time.